Assistenza presse iniezione suggest plastic for prototyping

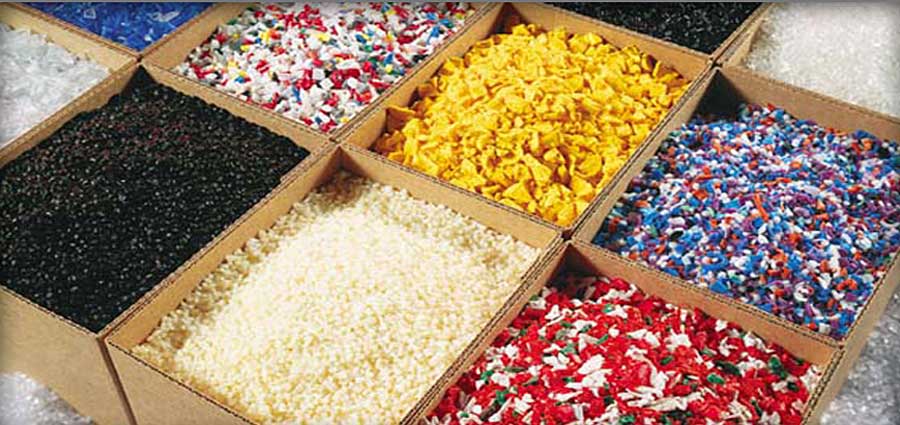

Plastic is among the more typically used materials for prototyping.

Product development designers, manufacturing professionals assistenza presse iniezione, developers, unique job leaders, and also retail and also production prototype professional turn to plastics to produce their moldings as well as models.

These people recognize that plastic can be formed, cut and adjusted whatsoever conceivable to develop prototypes that would certainly benefit the growth of their products.

Models from plastic can be decline evaluated, evaluated for toughness, decontaminated, checked for consumer choice and sturdiness, and can be taken into real use in no time at all at bare minimum prices.

With plastic prototyping, developers have various alternatives at their disposal. Designers and designers can utilize rapid prototyping methods which have devices like stereolithography, deposition modeling, laser sintering, laminated item production, as well as 3 dimensional printing at its forefront.

All these integrates the fundamentals of fast prototyping, each strategy creates specific parts from 3D-CAR models and joins them as layers till the last prototype is ended up.

Utilizing quick prototyping methods permits quick reproduction of models regardless of the intricacy of forms.

It could be low-cost at initial but considering that each component is produced individually, manufacturing costs may go up as the number of parts needed rises. Likewise, last result constantly have rough coating which brings the need to polish each part as they appear of their moldings.

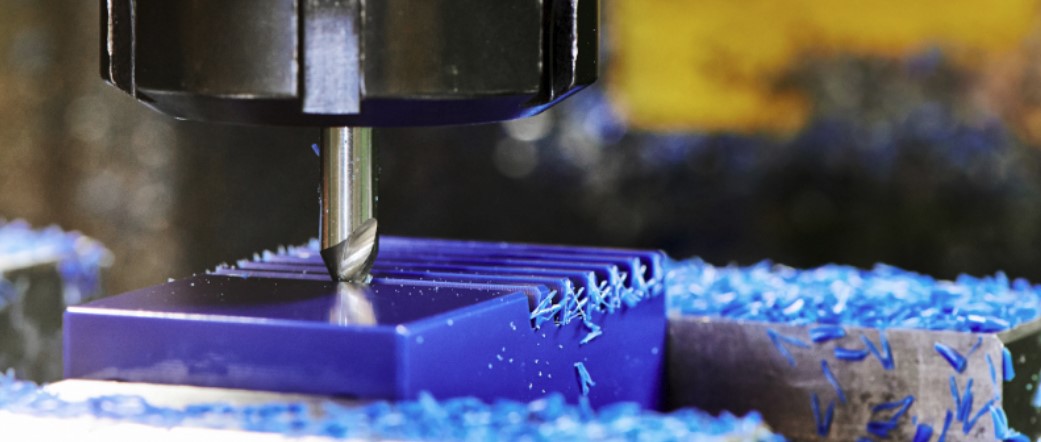

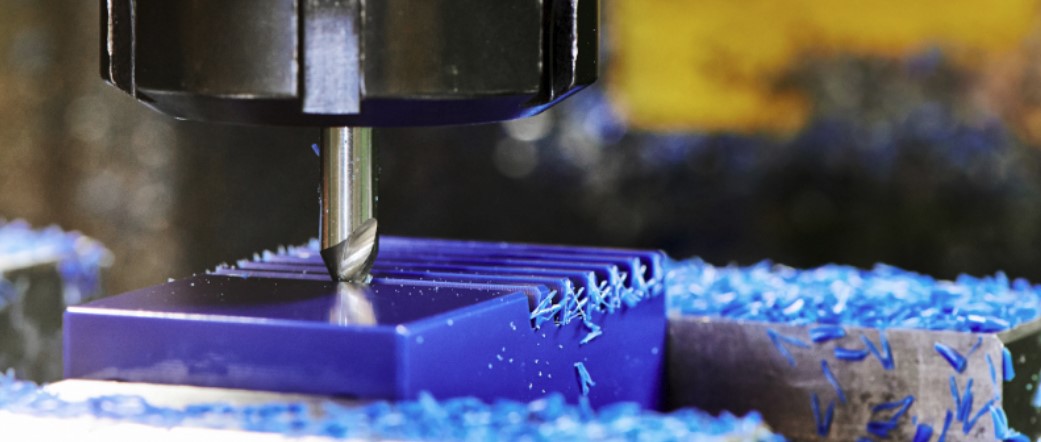

An alternative is quick shot molding techniques which includes making use of steel mold and mildews. This technique is able to create plastic components that are totally functional and have an excellent finish. Given that the molds are constructed from steel, they have the ability to sustain a larger range of materials and also can appear as a whole lot more affordable than rapid prototyping or rapid tooling.

Regardless of the method

the resulting plastic model need to include the top qualities of much less manufacturing expenses and also more speed in manufacturing. The finished part also has to stick to particular requirements.

Any kind of model component have to imitate the shape, dimension, finish and also even color of the last manufacturing component. And also any kind of prototype part should at the very least resemble the production component’s strength, chemical resistance, versatility, durability and also warmth tolerance just to name a few.

Plastic is a very good product to create models which can be constructed, examined and also made use of as close as the production parts.

Using the appropriate prototyping techniques can save you time and money as well as allow you to simplify your manufacturing procedure, both for the model and the real manufacturing system. Remember that if the prototype is excellent, the final product can be excellent.

An alternative is rapid injection molding strategies which incorporates the use of steel molds.

This technique is able to produce plastic components that are fully practical as well as have a good surface.

Considering that the mold and mildews are made of metal, they are able to sustain a wider array of materials and also can come out as a whole lot cheaper than fast prototyping or rapid tooling.

About The Author